Electric Power Solutions

Hybrid and fully electric solutions

Our in-house developed electric solutions draw on Scania´s long experience, knowledge, and technology from electrifying on-road vehicles, resulting in high system reliability and outstanding performance in a compact design.

This also facilitates builder design, installation, and maintenance. Like all Scania power systems, the electric components are modular and scalable, and thereby suitable for a number of different applications.

All components work seamlessly together and are controlled with a common management system, while standard mechanical interfaces simplify integration with external components. With impeccable interaction between different components to achieve full system integration, electrifying vehicles, vessels, or equipment has never been smoother.

Electrified marine solutions

No matter if you're looking to increase performance, or reduce emissions and fuel consumption – we have both hybrid and battery electric solutions that make the most out of your vessel, in a sustainable way.

Electrified industrial solutions

Industrial equipment comes in many types, shapes and sizes, and we offer electrified power solutions for different applications and areas of usage. Both hybrid, and fully electric.

Powering the journey to electrification

Scania is proud to be driving change for a more sustainable tomorrow – a challenge we don’t take lightly. While we believe the future is electric, and lead strong research and development in this area, we also know fully electric solutions aren’t feasible in all applications – yet. That’s why we work just as hard to reduce the environmental impact of our internal combustion engine (ICE) technology, and will do so for as long as those solutions remain in use. Both in standalone operation, as well as in hybrid electric configurations with renewable fuels and green electricity working together to push us forward.

Hybrid electric

Scania´s hybrid electric power systems allow for the engine and e-machine respectively to be run together or as standalone power sources.

The adapted speed range of the electric machine means that a reduction gear can be avoided, minimising energy loss and facilitating equipment design and installation. Altogether, the system enables improved powertrain performance with exceptional torque and response directly from idling, lowered fuel consumption that reduces operational cost and emissions, as well as minimised noise when and where needed.

With the option to also operate fully emissions free when needed, operations in especially emissions sensitive contexts such as marine operations in environmentally protected waterways is made possible.

Fully electric

The high power density electric machine offers maximum torque and response directly from start.

In combination with state-of-the-art batteries and other adjacent components, it eliminates tailpipe emissions and removes powertrain noise. In addition, the low maintenance requirements help reduce operational cost.

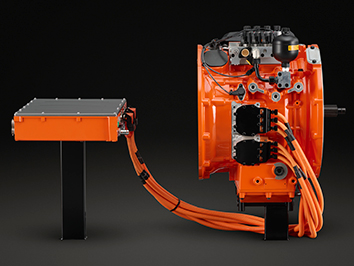

Electric machine

Power*

230 kW continuous @ 2,100 rpm

295 kW peak @ 1,400 rpm

Torque*

1,400 Nm continuous

2,000 Nm peak @ 0–1,400 rpm

Speed range

0-2,900 rpm

System voltage

650 V (DC)

Cooling

Oil cooled

Weight

280 kg (including inverter)

Dimensions (L x W x H)

495 x 660 x 710 mm

*The performance figures are dependent to certain conditions

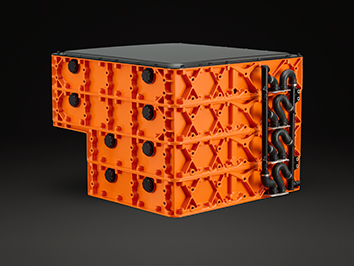

Battery pack

Configuration CBP MP10

Cell chemistry

Lithium Ion NMC / graphite

Installed energy* 100 kWh,

also available in 200 kWh

System nominal voltage*

650 VDC

Installed capacity* 157 Ah

C-rate (Discharge/Charge)

Up to 1.6/Up to 1.3

Continuous power (Discharge/Charge)*

160 kW/125 kW

Weight ~620 kg

Dimensions (L x W x H)

832 x 775 x 636 mm

*Performance figures based on beginning of life @SOH 100% and depending on usable energy factor and SOC

Frequently Asked Questions about electrified power systems

When it comes to the initial investment, then in many cases yes – it can add cost up front. But when looking at total cost of ownership and running operational costs, savings from reduced fuel costs add up quickly. Additional cost can also be offset by allowing downsized solutions – e.g. by choosing a smaller ICE-engine in a hybrid solution without compromising on performance.

Both, in fact. Because even if it may feel counterintuitive, in many ways they go hand in hand. Do you want even more power than our most powerful V8? Add an electric motor in hybrid configuration, and the result can be immediate, and without needing a full equipment redesign for a dual ICE-engine configuration.

But at the same time, in any situation where you are not constantly operating at maximum power, adding the electric machine can allow your ICE-engine to run less, with lower fuel consumption and emissions as a result. And if you are happy with your current performance levels, you can now achieve the same by downsizing to a more fuel efficient powertrain – with the same results.

Yes, and no. While a hybrid powertrain does add complexity, it also adds redundancy. Our hybrid powertrains can for example decouple the electric machine from the ICE-engine and run it independently to keep your equipment or vehicle in operation under pure battery power for a while. And with all components coming from Scania as a complete solution – you can also trust that we take full responsibility to keep every part of it operating at peak performance.

For maintenance of the ICE-part of the powertrain, of course – we use our standard Scania engines with standardised parts and components. Working safely on the electric components however requires high-voltage certifications, and that’s something we can help you with.

Scania's quality track record comes from never doing something we don't know we can do at the highest possible quality and reliability. This goes for electric power as well. We also take full responsibility for the full solution, not just ICE engine, e-machines and batteries by themselves – but how it all works together. With engine and battery management systems, charging systems and strategies as well as the digital services that let you have full control.

Battery recycling service

No-cost battery recycling program to ensure minimum climate impact.

A Scania battery that is no longer fit for purpose can always be returned to us at zero additional cost – and we have the logistics flow and recycling partners to ensure it can be handled in a circular way.

Marell high-speed boat powered by electric Scania solution

Marell Boats founder and owner Patrik Söderholm makes fast aluminium patrol boats running on electricity. The journey of a lifetime all began in his grandfather’s fishing boat.

M/s Rex – a hybrid marine powertrain in action

Hybrid powertrain solutions offer the natural first step for electrifying marine operations – providing the benefits from both combustion engines and e-machines, using well proven hybrid technologies from our road vehicles.

Register your power system for warranty coverage and support

By knowing more about your machinery and operation, we can support you in the best way. For that reason, and to ensure warranty coverage for your power system, we ask you to report the warranty start date for your new engine or electric machine.

Power Solutions around the world

Explore Scania's offerings in your country! If the products aren't available in your local market, you'll be redirected to the start page.

Scania international sales

Get in contact with Scania international sales at head office to talk about our power solution systems